JOIN THE GIANT NEWSLETTER!

Subcribe for New product arrivals, Market updates, and Promotional Events etc.

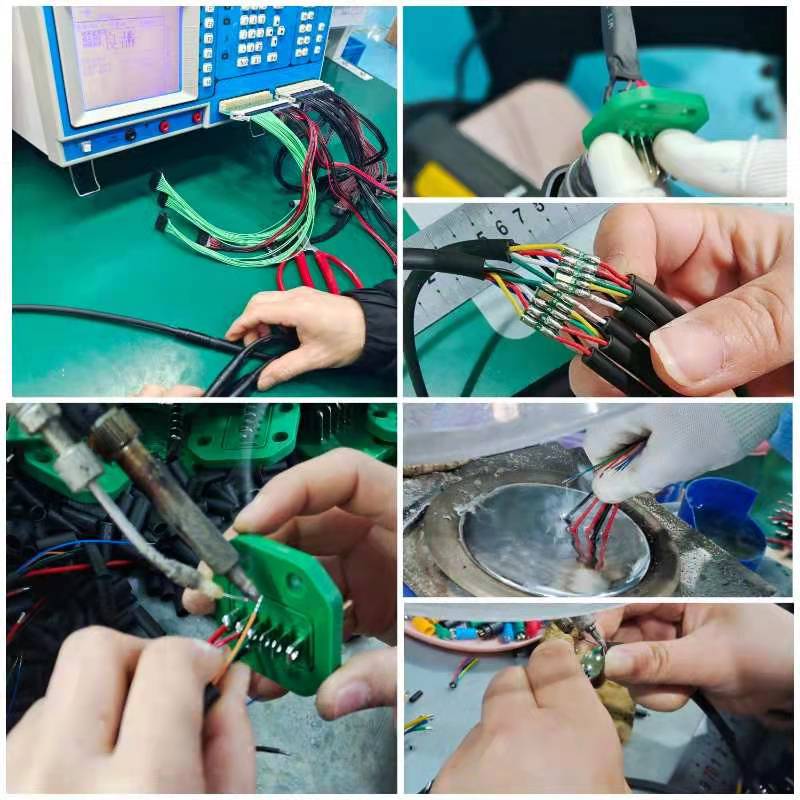

E-bike components, such as the throttle, motor and battery, usually come with some type of plastic electrical connector on the end of the wire. These connectors plug into the e-bike's controller and make it easy to connect everything together.

In theory, these connectors also make it easy to remove one component and replace it with another in its place. Today we will learn how to easily replace the connectors on any e-bike component.

Here you can see my new throttle cable at the top. The first thing to do is cut off the old connector, just like I did with the black 3-pin connector, in preparation for swapping it onto my new throttle cable. Leave at least a few inches of wire on the connector so that you can easily solder it to the wires of the new assembly.

Next, disconnect the connector from the new throttle. You may want to save it in case you need it again. I have a box full of connectors for just this purpose. Visit GRAND's website to find the right connector and cable.

Strip about 1/8" to 1/4" of wire from the end of the wire on the throttle cable and connector cable.

You will need to apply solder to the bare ends of the wires. Generally, you want to apply the tip of the soldering iron to the copper wire to start heating the wire. After a few seconds, apply the solder directly to the wire until the bare end of the wire is coated with solder.

Heat shrink tubing covers and isolates electrical connections from each other, which is very important for e-bike connections. Cut your heat shrink tubing into sections about an inch long and slide it onto the wire on the side with the longer single wire.

Spiral power cable for electric bike electric scooter

Now that you have the heat shrink tubing in place, you are ready to start making the solder connection. The solder will melt and connect the two wires together. Once the solder is melted, leave the iron in place for a second or two to make sure the two wires are well fused to the wet solder, then remove the iron.

Once the connections are secure, you will need to slide the heat shrink tubing into place and seal it with a heat gun. Do not try to use a hair dryer; you will need a real heat gun. You must be very careful not to damage the heat shrink or the insulation of the wire. Heat shrink connector with heat gun.

Basically, you are done. As long as you have matched the wires correctly, soldered them in place and covered them with heat shrink, then you are ready to connect your unit and get your e-bike going again.

Please drop us a line to get a quote on a power cord and we'll be happy to help you out.

JOIN THE GIANT NEWSLETTER!

Subcribe for New product arrivals, Market updates, and Promotional Events etc.

Suzhou Grand Electronic Technology Co., Ltd. is a high-tech enterprise that produces advanced waterproof cables. It is located in Dongshan Town, Wuzhong District, Suzhou City, China, in the Jiangsu-Zhejiang-Shanghai Economic Triangle.

Copyright © Suzhou Grand Electronic Tech Co., Ltd. All Rights Reserved |

Sitemap

| Powered by